소개

스테인레스 스틸은 건설, 자동차, 항공우주 및 제조를 포함한 다양한 산업에서 가장 다양하고 널리 사용되는 재료 중 하나입니다. 내식성, 내구성 및 미학적 매력과 같은 독특한 특성은 많은 응용 프로그램을 위해 선호되는 선택으로 만듭니다.그러나 스테인리스 스틸을 절단하는 데 정밀성, 효율성 및 적절한 장비가 필요합니다.이것은 스테인리스 스틸 절단 기계가 게임에 들어오는 곳입니다.이 포함적인 가이드에서 우리는 스테인리스 스틸 절단 기계의 다양한 유형, 그 응용 프로그램 및 그들이 제공하는 혜택을 탐구할 것입니다.

스테인리스 스틸 절단기 유형

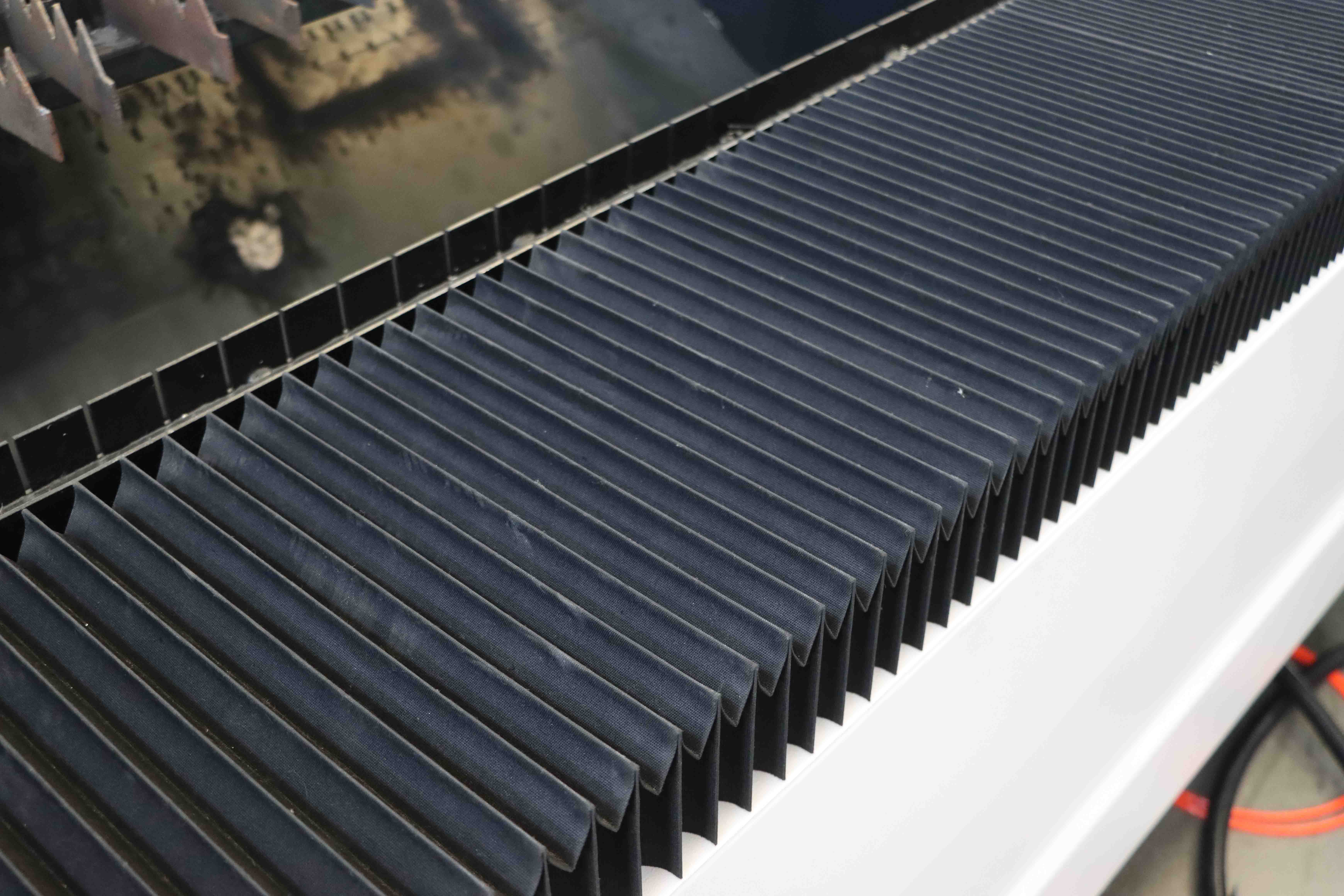

1. 레이저 절단기

- 광섬유 레이저 절단기: 이 기계들은 고출력 레이저 빔을 사용하여 매우 높은 정밀도로 스테인리스강을 절단한다.파이버 레이저는 속도, 정밀도 및 복잡한 형태를 절단하는 능력으로 유명합니다.그것들은 중간 두께로 얇은 스테인리스 강판에 특히 효과가 있다.

- CO2 Laser Cutting Machines: CO2 lasers are another popular option for cutting stainless steel. They are suitable for thicker materials and offer excellent edge quality. However, they are generally slower than fiber lasers and require more maintenance.

2. Plasma Cutting Machines

- Plasma cutting machines use a high-velocity jet of ionized gas to cut through stainless steel. They are ideal for cutting thick materials and are known for their speed and cost-effectiveness. However, they may not offer the same level of precision as laser cutting machines.

3. Waterjet Cutting Machines

- Waterjet cutting machines use a high-pressure stream of water mixed with abrasive particles to cut through stainless steel. They are versatile and can cut a wide range of materials, including stainless steel, without generating heat. This makes them suitable for applications where thermal distortion is a concern.

4. Shearing Machines

- Shearing machines use a blade to cut through stainless steel sheets. They are suitable for straight cuts and are often used in high-volume production environments. However, they are limited in their ability to cut complex shapes.

5. CNC Cutting Machines

- CNC (Computer Numerical Control) cutting machines are automated systems that can be equipped with various cutting tools, including lasers, plasma torches, and waterjets. They offer high precision and are capable of cutting complex shapes and patterns.

Applications of Stainless Steel Cutting Machines

1. Construction Industry

- Stainless steel cutting machines are widely used in the construction industry for cutting structural components, cladding, and decorative elements. The precision and efficiency of these machines ensure that the materials meet the required specifications.

2. Automotive Industry

- In the automotive industry, stainless steel cutting machines are used to cut components such as exhaust systems, body panels, and chassis parts. The ability to cut complex shapes and achieve high precision is crucial in this industry.

3. Aerospace Industry

- The aerospace industry demands high precision and quality in the materials used. Stainless steel cutting machines are used to cut components such as engine parts, structural elements, and fuel tanks. The ability to cut without generating heat is particularly important in this industry.

4. Manufacturing Industry

- In the manufacturing industry, stainless steel cutting machines are used to produce a wide range of products, including kitchen appliances, medical devices, and industrial equipment. The versatility and efficiency of these machines make them indispensable in high-volume production environments.

5. Art and Design

- Stainless steel cutting machines are also used in the art and design industry to create intricate sculptures, decorative panels, and custom furniture. The ability to cut complex shapes and achieve high precision allows artists and designers to bring their creative visions to life.

Benefits of Stainless Steel Cutting Machines

1. Precision and Accuracy

- Stainless steel cutting machines offer exceptional precision and accuracy, ensuring that the cut materials meet the required specifications. This is particularly important in industries where tight tolerances are critical.

2. Efficiency and Speed

- These machines are designed to cut stainless steel quickly and efficiently, reducing production time and increasing throughput. This is especially beneficial in high-volume production environments.

3. Versatility

- Stainless steel cutting machines are versatile and can be used to cut a wide range of materials, including stainless steel, aluminum, and other metals. This makes them suitable for various applications across different industries.

4. Cost-Effectiveness

- While the initial investment in a stainless steel cutting machine may be high, the long-term cost savings are significant. These machines reduce material waste, minimize the need for secondary processing, and increase overall productivity.

5. Quality and Consistency

- Stainless steel cutting machines produce high-quality cuts with consistent results. This ensures that the finished products meet the required standards and specifications.

6. Safety

- Modern stainless steel cutting machines are equipped with advanced safety features, such as automatic shut-off mechanisms and protective enclosures. This reduces the risk of accidents and ensures a safe working environment.

Conclusion

Stainless steel cutting machines are essential tools in various industries, offering precision, efficiency, and versatility. Whether you are in the construction, automotive, aerospace, manufacturing, or art and design industry, these machines can help you achieve high-quality results and increase productivity. By understanding the different types of stainless steel cutting machines, their applications, and the benefits they offer, you can make an informed decision and choose the right machine for your needs. Investing in a high-quality stainless steel cutting machine is a smart move that will pay off in the long run, ensuring that you stay competitive in today's fast-paced and demanding market.

일반적인 조언이나 특정 지원이 필요하든 상관없이, 우리는 당신을 도와드릴 것입니다.