Safe, Fast & Automated Fiber Laser Cutting

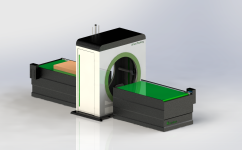

The Roclas Fiber Laser Cutting Machine stands out in the industry with its innovative design and cutting-edge technology. One of its most notable features is the fully enclosed sheet metal structure, which completely isolates laser radiation and processing dust. This design not only ensures the highest level of safety but also significantly reduces operational noise, creating a comfortable and quiet working environment. The seamless integration of these elements makes the machine both safe and pleasant to use, setting a new standard for industrial equipment.

Beyond safety, the machine excels in operational efficiency. Its platform automatic exchange system and process reengineering enable 24-hour continuous processing, eliminating the need for manual intervention. This automation reduces labor time and boosts overall cutting efficiency by 50-80%, making it a game-changer for high-volume production. The machine's ability to operate around the clock without compromising performance ensures consistent output, meeting the demands of modern manufacturing.

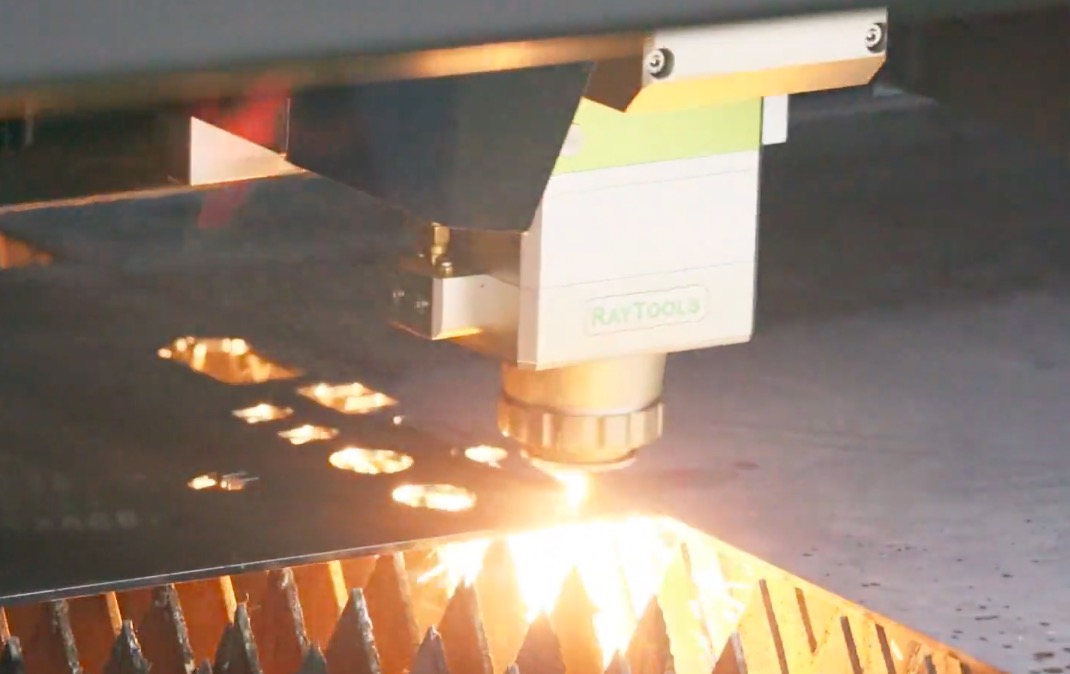

For thin plate cutting, the machine is particularly impressive. It eliminates the need for lift-off waiting, allowing instant penetration of materials. This specialized optimization drastically shortens processing cycles, positioning the machine as a leader in speed and responsiveness. Whether dealing with delicate materials or tight deadlines, the Roclas Fiber Laser Cutting Machine delivers unmatched performance, ensuring quick and precise results every time. The machine's intelligent collision avoidance system is another standout feature, designed to ensure smooth and uninterrupted operation. Equipped with high-sensitivity sensors in the laser head, it constantly monitors the working environment. When combined with advanced path avoidance algorithms, the system can detect and react to lifted workpieces in milliseconds, significantly reducing collision risks. This not only protects the machine from damage but also maintains continuous processing, minimizing downtime and maximizing productivity. Operators can work with confidence, knowing the system will automatically adjust to prevent accidents, even during complex cutting tasks.

User-friendliness is at the core of the machine's design, making it accessible to operators of all skill levels. The intuitive graphical interface simplifies navigation, while the built-in database of cutting parameters and preset modes eliminates guesswork. With just a few clicks, users can select the optimal settings for different materials and thicknesses, ensuring precise cuts without extensive manual adjustments. This streamlined approach reduces training time and minimizes errors, allowing teams to focus on production rather than troubleshooting. The system's adaptability means it can handle a wide range of materials, from carbon steel to aluminum, with consistent quality and ease of use. The machine's cutting performance is truly exceptional, combining speed and precision to deliver outstanding results. With a maximum linkage speed of 180m/min and 2G acceleration, it operates at industry-leading velocities without sacrificing accuracy. The integration of 8Hz low-pass filter technology ensures smooth, high-quality cuts even at high speeds, producing clean edges free from burrs. This level of precision not only enhances the final product's appearance but also reduces the need for secondary finishing, saving both time and material costs. The machine's ability to maintain such high standards consistently makes it a reliable choice for demanding applications.

Built to last, the machine features a robust structure that ensures long-term stability and reliability. The high-rigidity bed frame and precision transmission system work together to maintain cutting accuracy, even during prolonged high-speed operation. This durability is complemented by its versatility, as it can effortlessly handle a variety of materials, including carbon steel, stainless steel, aluminum, and brass. The machine's adaptability to different materials expands its utility across industries, providing a one-stop solution for diverse cutting needs. Its consistent performance over time makes it a valuable asset for any production environment.

To further enhance productivity, the machine offers optional automatic loading devices that seamlessly integrate with exchange worktables. This setup enables true "cutting and loading/unloading parallel operation," maximizing equipment utilization to over 90%. By eliminating idle time during material changes, the system achieves a significant leap in production efficiency. Additionally, the intelligent nesting software optimizes material layout, minimizing waste and contributing to cost-effective, eco-friendly production. These features collectively transform the machine into a powerhouse of efficiency, driving both operational and economic benefits.

Previous:Why Choose Roclas Fiber Laser Cutting for Your Metalworking Needs

Next:Not

Get a Quote

Regardless of whether you require general advice or specific support, we are happy to help you.